Asset Life Assessment of refinery equipment

Asset Life Assessment of refinery equipment

By: Dr. Marco Mucino

Asset Life Assessment Project:

Whitecastle Engineering Limited (WEL) successfully completed the Asset Life Assessment (ALA) of rotating and production equipment, from two refinery plants in Europe. This project was part of a global initiative by a large petrochemical company to produce the sustainable and profitable long term financial and operational strategies for the business.

Gathering the Data

WEL reviewed all available design, field and operational data including that acquired during our own site survey of the facility. A thorough inventory of all major equipment assets was compiled and then each individual piece of plant was assessed for its current state of performance against the sights optimum requirements.

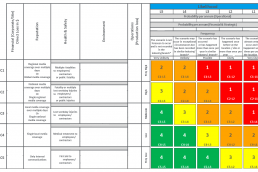

Damage mechanism and Risk Level

As part of the ALA, WEL conducted a qualitative and quantitative assessment of the current equipment including the evaluation of the main damage mechanisms and potential mitigation actions. The Risk Level assessment, part of the ALA, was conducted using experience, publicly available data and historical operational and maintenance records. The financial/operational/safety/environmental consequence deriving from the main damage mechanisms, and the probability of such event occurring, were used to define a Level of Risk for that particular asset.

Level of investment and recommended execution timeframe

The damage mechanisms, mitigation actions and risk level information was used to generate a number of high level operational, maintenance and financial planning scenarios from where a short or long term budget was estimated. WEL gave a recommended timeframe for the outlay of resources and execution.

Related Posts

Asset Life Assessment of refinery equipment

News,Asset Life Assessment,Risk Assessment

Whitecastle Engineering Limited (WEL) successfully completed the Asset Life Assessment (ALA) of rotating and production equipment, from two refinery plants in Europe.

Gas Turbine Air Filtration Optimisation

Gas Turbines,Troubleshooting Analysis,News,Production Optimisation

Recently Whitecastle Engineering Ltd (WEL) was commissioned to undertake a study regarding an issue with the performance of an Ethylene Plant built in the 1980’s.

Gas Turbine Air Filtration Optimisation

Gas Turbine Air Filtration Optimisation

By: Dr. Marco Mucino

Lack of compression a production issue

Recently Whitecastle Engineering Ltd (WEL) was commissioned to undertake a study regarding an issue with the performance of an Ethylene Plant built in the 1980’s. The gas turbine driving a process gas compression train had been underperforming for some time and the production of the plant was being affected accordingly. WEL were asked to identify the problems and were possible provided recommendations for a solution.

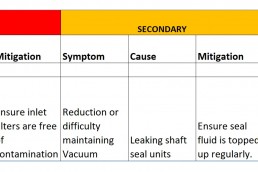

Air filtration Problem Identified.

WEL reviewed all available data and undertook a survey of the site in order to best ascertain the size and extent of the issues. Upon analysis of the acquired data it was determined that the main issue over and above that of poor maintenance was the need to upgrade old, ineffective and expensive air filtration elements.

Instrumentation deficiencies

WEL identified the lack of instrumentation that had not highlighted key issues such as punctures in the air ducts that were allowing unfiltered air into the turbine as well as the blow back filter cleaning function being inoperative and insufficient even if in full service.

Recommendations and Solutions

WEL put forward practical recommendations in the selection of alternative schemes emphasising on the pros and cons of each option. WEL recommended upgrading the filter element to a HEPA E10 filters which provided the best cost/benefit ratio from the various options analysed.

Related Posts

Asset Life Assessment of refinery equipment

News,Asset Life Assessment,Risk Assessment

Whitecastle Engineering Limited (WEL) successfully completed the Asset Life Assessment (ALA) of rotating and production equipment, from two refinery plants in Europe.

Gas Turbine Air Filtration Optimisation

Gas Turbines,Troubleshooting Analysis,News,Production Optimisation

Recently Whitecastle Engineering Ltd (WEL) was commissioned to undertake a study regarding an issue with the performance of an Ethylene Plant built in the 1980’s.

Air Compressor Reliability Analysis

Air Compressor Reliability Analysis

By: Dr. Marco Mucino, Alan Ranger

Compression issues increase costs and decrease production

Whitecastle Engineering Ltd (WEL) were recently contracted to undertake a reliability review of air compression issues on an Ethylene Plant in the UK. Continuing problems with the onsite compressors had led to an over reliance upon temporary rented mobile compression units and the situation was only getting worse as down time on the on-site compression packages became ever longer and more regular. WEL reviewed performance data, maintenance records, design data and specifications and conducted specialist thermal modelling and simulations of heat exchanger within the package.

Compressor Issues Identified

Following our review we were able to ascertain that the situation had been caused by a number of differing factors that had come together to cause this out of control state of events, key identified areas of concern that were in need of corrective action were:

The reliance on the OEM to drive the maintenance plan and, indirectly, the risk assessment of their assets generated a vacuum of on-site expertise and resources that had a knock-on effect on the assets reliability and availability.

Negative Cost Implications

This situation had a negative effect on the cost of ownership due to the repeated hire of temporary air compression units to cover downtime of site machinery.

Problems Identified

The reliability of the compressors was mainly affected by considerable compressor screw element performance degradation caused by water ingress and heat exchanger integrity failure and performance degradation caused by the cooling water subsystem undesirable off-design operation. These two caused among several other factors were discovered to be responsible for the regular failure cycle.

Life Time Cycle Cost Reduction

WEL produced a report that outlined a series of corrective actions and defined the available technical alternatives for the optimisation of the system with input from various vendors and then conducted a feasibility analysis to evaluate the technical and economic merits of each option and recommend the preferred solution that would reduce the risk of plant shutdown due to failure of the air compression system by Increasing the reliability and availability of the system and ultimately reducing life time cycle costs.

Related Posts

Asset Life Assessment of refinery equipment

News,Asset Life Assessment,Risk Assessment

Whitecastle Engineering Limited (WEL) successfully completed the Asset Life Assessment (ALA) of rotating and production equipment, from two refinery plants in Europe.

Gas Turbine Air Filtration Optimisation

Gas Turbines,Troubleshooting Analysis,News,Production Optimisation

Recently Whitecastle Engineering Ltd (WEL) was commissioned to undertake a study regarding an issue with the performance of an Ethylene Plant built in the 1980’s.