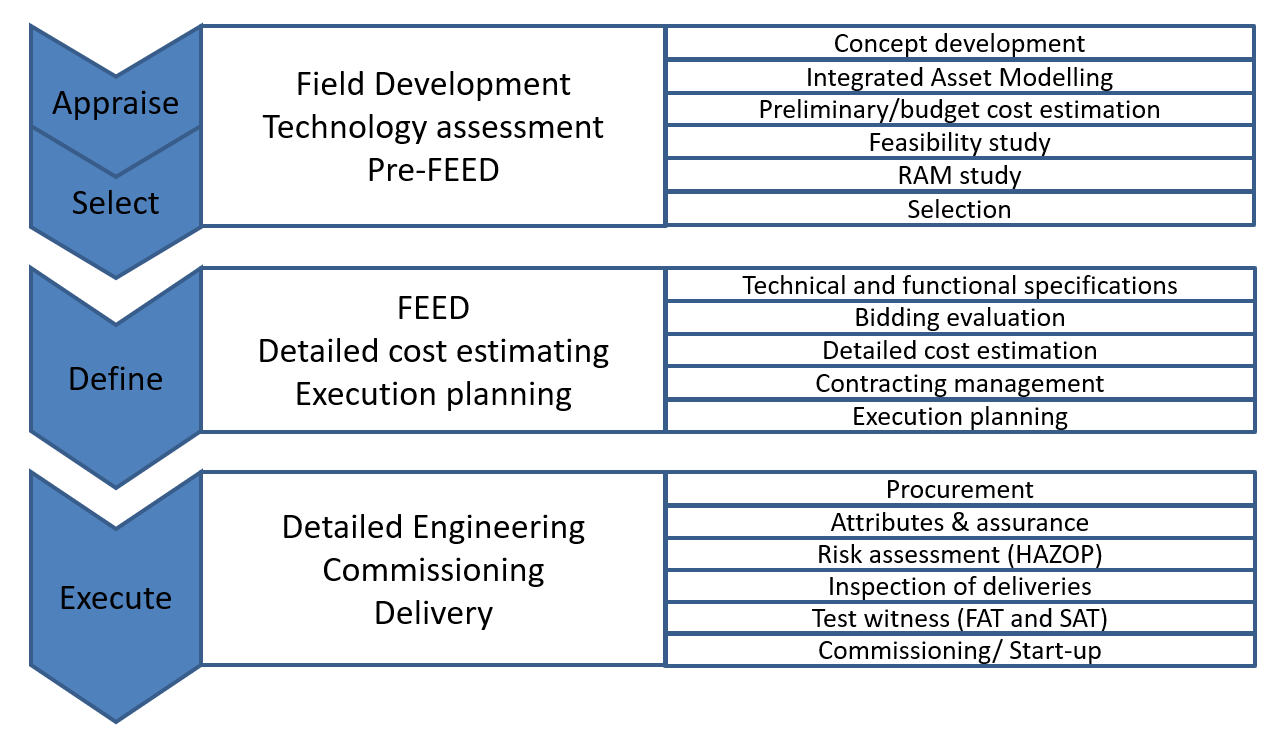

Project Lifecycle

Whitecastle follows these three undeniable facts:

- Most of the realisable savings in a project are made at the APPRAISE/SELECT phase.

- DEFINE provides a considerable scope and opportunity to effectively hedge the risk in a project.

- The quality of the project is planned, controlled and delivered during EXECUTE.

Appraise / Select

Whitecastle Engineering follows a rigorous method to design, evaluate and select progressively complex technical options so our clients have the opportunity to decide at what level of investment and technical quality they want to implement in the project.

As part of the Appraise/Select project stage we provide the following solutions and services:

- Feasibility analysis of machinery-based systems

- Configuration optimisation for asset lifecycle

- Machinery technology assessment

- Process modelling of proposed solutions

- Aero-thermodynamic preliminary design of machinery

- CAPEX and OPEX calculations

- Techno-economic analysis

- Integrated Asset Modelling

- Preliminary/Budget cost analysis

- RAM analysis

Define

Whitecastle Engineering has proven track record of reducing costs and risks of our clients’ projects by producing accurate technical specification documents, which, in turn, influence vendor bids to deliver on the critical requirements of the project, rather than pursuing a different agenda.

We conduct independent technical and commercial assessments of the vendors’ bids leveraging our 40+ years worth of experience in projects with machinery as critical equipment. Our assessments are distinctive in the use of advanced modelling techniques of machinery and production systems to support our conclusions and recommendations.

We liaise with vendors during the bid clarification process and hold engineering meetings with the project team to select the best technically and commercially viable solution offered by vendors.

As part of the DEFINE project stage we provide the following solutions and services:

- Technical specification documentation

- Independent Project documentation review

- Bid evaluation management

- Detailed cost estimation

- Owner’s engineer support

- Execution planning

Execute

During EXECUTE, our engineers play an active role as part of our client’s project team: attending design and engineering meetings, reviewing project engineering documentation, reviewing and approving technical drawings, attending factory and site tests, and supporting risk assessment activities.

We provide technical expert support to assure and control quality of the deliverables addressing design and construction punctual aspects: materials selection for harsh conditions, dimensional and functional interface assessment in brownfield projects, machinery alignment, health and safety features, among many others.

In the role of Expert Witness we take responsibility of Factory and Site Acceptance Testing of project process equipment, machinery and secondary systems on behalf of our clients. We review and comment testing procedures issued by EPC or vendors, prepare pre-test calculation sheets (if applicable), travel to factory or site, process test data and produce a report with recommendations. During the test it-self we make sure best practices for the collection of data, storage and application are followed.

During the EXECUTE project stage we provide the following solutions and services:

- Owner’s engineer services

- Procurement and contract analysis

- Quality Attributes and Assurance analysis

- Risk assessment analysis

- Inspection of deliverables

- Expert witness -Factory and Site Acceptance Testing

- Commissioning and Start-up support