Concept and Rating Design

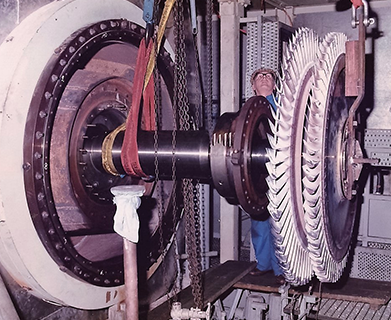

A large number of gas compressors operating in the Oil&Gas industry have a bespoke design specifically selected to deliver a set of operating parameters such as gas molecular weight, production volume, pressure ratio, capacity flexibility and power consumption (defining driver capacity).

However, over the life of the field/asset, these operating conditions will change and so does the optimum design of the compressor limiting or eliminating its original flexibility.

Whitecastle Engineering has a unique track record of delivering exceptional value to our customers through our Debottlenecking services that answers the main question in mind:

Performance Testing And Benchmarking

We provide performance testing solutions for power plants, gas compression systems and other machinery based systems, whether in the high-pressure environment of contractual acceptance tests or during a routine benchmark exercise.

We have the expertise and experience to identify deviations in best and standard practices during testing to eliminate or reduce the technical and financial risks associated with a false-positive test, in other words, incorrectly accepting an asset that will bring financial losses to the operator can be embarrassing.

Root Cause Analysis

Whitecastle Engineering has proven track record conducting and delivering successful Root-Cause-Analysis solutions to clients in Europe and Middle East.

Our unique combination of hands-on and analytical skills and expertise allow us to absorb, analyse and identify the root of the problem using Ishikawa’s 5 M’s methodology effectively.

We have worked for operators and OEMs alike as they recognise our expertise in the business.

Troubleshooting Analysis

A more agile and pragmatic service for an operator in need of immediate technical expertise during unscheduled and sudden outages.

Our Machinery Troubleshooting service can be performed on- and off-site: it is supported by advanced simulations and analysis when data is available. Our extended group of associates, colleagues and professional contacts gives us a competitive advantage we put to the service of our clients.

Energy Efficiency Analysis

A hot topic in the last few years, an Energy Efficiency Analysis of an asset or production system is the systematic scrutiny of the inputs and outputs of energy streams within that system.

Whitecastle Engineering has post-graduate degree trained engineers able to conduct a detailed thermo-economic analysis of the main equipment and energy streams inside a production system. We make use of the latest technology to provide rigour to our analysis.

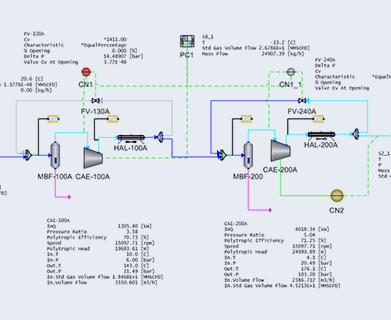

Steady-State and Dynamic Simulation

We simulate process, machinery and power systems steady-state and dynamic behaviour using advanced thermodynamic programmes such as HYSYS, VMG, VirtualPlant, GateCycle, etc.

We have consultants with post-graduate degree expertise level on performance and thermodynamic of Combined Cycle Power Plants, Rankine Cycle Power Plants, Gas Compressions Systems, Water Pumping systems, etc.

We use our dynamic simulation expertise to analyse, propose and test changes to operational conditions and limits, or control logic and/or configuration.

Do you know how valuable is having a rigorous model of your assets?

Maintenance and Spare Management

Insufficient or inadequate maintenance can lead to a short run time depending on the nature of the item. Wholesale replacement of all parts is not a guarantee for success: it can be very expensive and increases dependency from parts manufacturers.

Understanding the equipment can pay dividends in knowing what to replace, what to overhaul or what to exchange for a reconditioned part.

Legacy Equipment Management

Whitecastle Engineering has many years of cumulative experience and knowledge of a wide variety of plant and equipment with particular experience of what is now known as legacy equipment.

Legacy equipment is the term given to old machinery equipment that is no longer manufactured but is still very capable of delivering the results originally installed to provide.

Whitecastle Engineering specialise in keeping older legacy equipment in service for as long as is reasonably possible and practical.

Do you really have to invest in new equipment?

Condition Monitoring

The use of Condition Monitoring Systems on Power and Process Plants is well documented and the display of the information a common feature in control rooms.

However, the appropriate use of the data or, in fact, the monitoring of the right Key Performance Indicators (KPI) tends to reduce the effectiveness of the systems.

Our engineers have proven experience delivering effective, bespoke Condition Monitoring systems for Power Plants and Gas Compression systems in the European, North and South American.

We also provide preliminary services such as instrumentation assessment and plant energy audit analysis. Our experience includes delivering personnel training courses at different levels of the organisation.