Asset Life Assessment of refinery equipment

By: Dr. Marco Mucino

Asset Life Assessment Project:

Whitecastle Engineering Limited (WEL) successfully completed the Asset Life Assessment (ALA) of rotating and production equipment, from two refinery plants in Europe. This project was part of a global initiative by a large petrochemical company to produce the sustainable and profitable long term financial and operational strategies for the business.

Gathering the Data

WEL reviewed all available design, field and operational data including that acquired during our own site survey of the facility. A thorough inventory of all major equipment assets was compiled and then each individual piece of plant was assessed for its current state of performance against the sights optimum requirements.

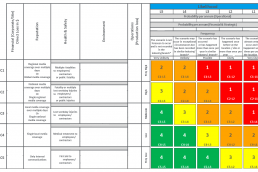

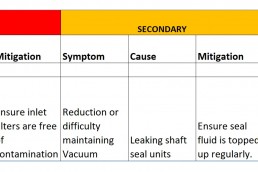

Damage mechanism and Risk Level

As part of the ALA, WEL conducted a qualitative and quantitative assessment of the current equipment including the evaluation of the main damage mechanisms and potential mitigation actions. The Risk Level assessment, part of the ALA, was conducted using experience, publicly available data and historical operational and maintenance records. The financial/operational/safety/environmental consequence deriving from the main damage mechanisms, and the probability of such event occurring, were used to define a Level of Risk for that particular asset.

Level of investment and recommended execution timeframe

The damage mechanisms, mitigation actions and risk level information was used to generate a number of high level operational, maintenance and financial planning scenarios from where a short or long term budget was estimated. WEL gave a recommended timeframe for the outlay of resources and execution.